Now on the dock at La Playita Marina, we set about getting Villa’s engine back in fighting form. One theory on why we’ve had so many sheared bolts lately is that our engine mounts are past their prime, which makes them stiffer and worse at damping the motor’s vibration. So we had ordered a new set from Las Perlas, and when they came in, we had a couple of professionals come and install them. We were expecting to have to lift the engine, but it turned out that they were able to install them in place, by just replacing one foot at a time. (Could we do this ourselves? Probably, but we just couldn’t bear the thought of trying to learn how to align the transmission right now.) It turned out that the old mounts were the wrong hardness, stiffer than Yanmar’s recommendation, which could also have contributed to the problem. Andrew supervised the installation, which mostly meant taking pictures and listening to the head mechanic talk about how much better he is than all the younger mechanics, and repeatedly steering the conversation back to the engine to try to extract nuggets of knowledge.

Meanwhile, Jazz was taking Uber ride after Uber ride across the city, going to all the biggest metal shops trying to find someone who stocked tubing with a 10mm inner diameter and was open on a Good Friday in a 90% Catholic country. Her last straw was when she got the manager at the largest metal shop in the city to call, on his cell phone, the personal phone of the owner of the company they use to fabricate parts that aren’t imported; with no answer, she still took a 45-minute cab ride out to the fabrication shop to see if anyone was there. And that was where she gave up and came home. But on her arrival home, the guy from the shop that had destroyed our original texted that he’d come up with 10.3mm ID tubing, which we decided was close enough for an attempt. He was able to make a nice weld with a clean bead and nearly right angles, but without a size reference he didn’t know where to cut the tube, so he had to come out to our boat the following day to take measurements.

Even then, we only came close. Meanwhile, the Yanmar dealer who arranged the first flawed replica was trying to come up with a better replacement. He eventually found a shop that was open despite it being Semana Santa (Easter weekend), produced a straighter-looking copy, along with some custom washers to adjust the alignment of the water pump pulley. Unfortunately, said bracket copy was still nothing like square, the extra metal they added got in the way of the alternator when installing, and in any case the mounting bolt wouldn’t go all the way through it. Sigh. So Andrew spent two entire days trying to adjust the alignment of the best candidate with a dremel, definitely not the right tool for the job but the shops were closed and it’s what we had available. Dozens of slow grind-paint-check, grind-paint-check cycles, but eventually we got the pulley in the right place and at the right angle.

Somewhere along the way, he made the mistake of trying to upgrade the coolant drain valve, which turned into several days of waiting for various fixes of the resulting leak to dry. Fortunately this was mostly concurrent with the grinding, but it did take an extra day and necessitate an extra trip out to buy more coolant. So we had only turned the engine on a couple of times, trying to bleed the air out of the coolant system, when we eventually left on Thursday, April 21st. Speaking of leaks: we gave up on getting the “Shadow Drive” in our autopilot to seal without leaking, and just removed it. Now we have to press a button to turn off the autopilot instead of just cranking the wheel, but the oil stays in the system. Also Garmin promised us a replacement part if we ever get a stable address again.

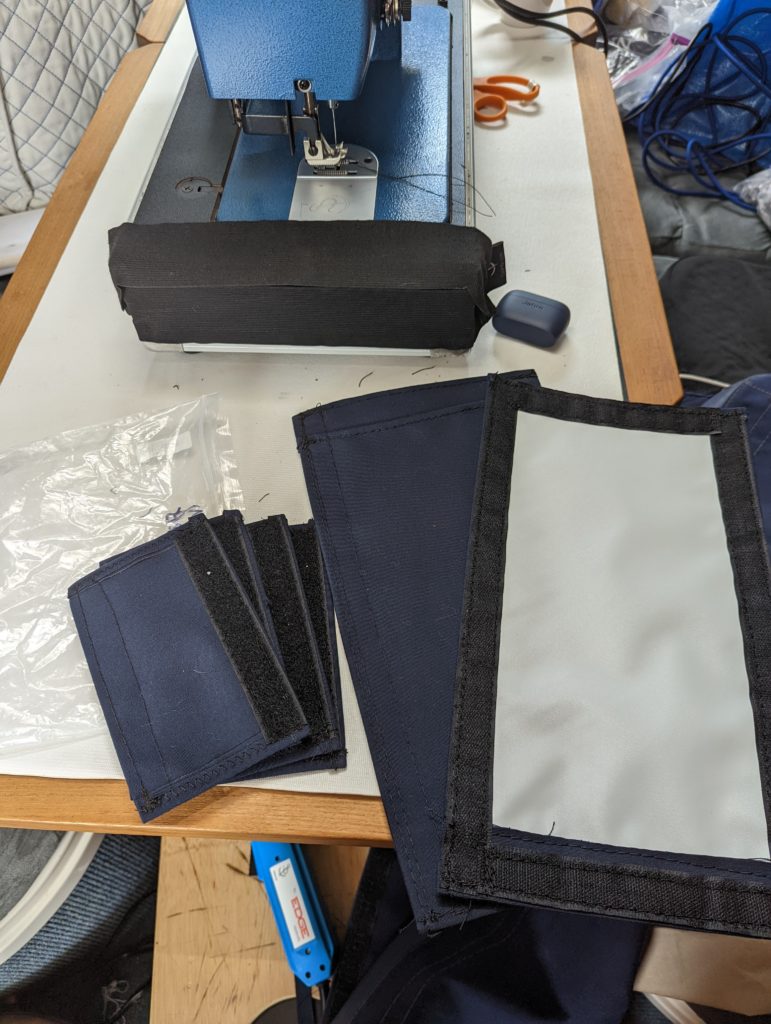

While Andrew dicked around with the engine, Jazz got out the Sailrite and started cranking out some other projects. We made some new mounts for our surf board, finally getting the PVC rod off of our deck; we had bought it in St Croix just over a year ago. She tagged our sun shades with red and green so we can tell which side is which. She made a new cover for the dinghy cowl, the one we had had made in Santa Marta turned out to be too small to fit and too poorly built to be worth repairing. And she added a panel with Dinkus’s name to the side of his chaps, and made some new sacrificial covers for his handles and davit wear points. She repaired the outdoor cushions, and the bathroom trash can, and Captain’s travel carrier. She made covers for the outdoor soap dispenser and for the new, tiny gas can we’d bought in hope of bartering fuel for tank fills from people with compressors. She added some clips to our back shades, and replaced some velcro on our cockpit roof shades. And the most difficult of all, she managed two new mosquito nets for our main salon windows, and now has a system she can use when we get to the rest. And we built a new shelf for the cat’s water fountain, using a cutting board because that’s the only structural material we can seem to find.

We got excited about getting a relatively late reservation for a “last dinner out” at a very nice restaurant, so we pulled out our formal clothes. Then they emailed to tell us that their online system was broken and that they actually didn’t have space until Tuesday. But the clothes were already out so we went out anyway, and had an amazing view and a disappointing dinner at Capital Bistro Panama.

It had been a while since either of us wore shoes, and the results were not great. Also we realized we don’t have any real vases on board; at least we got to use our dive weights for something in Panama.

One night, we heard a loud pop, came outside, and couldn’t see anything wrong so we went back to bed. In the morning, we found that the snubber on our dock line had popped. Ah well, we didn’t really need that anyway. Unrelated, we decided Jazz’s sailing gloves had seen enough love, and tried a new thing to keep the salt water in the chain and propane lockers more contained. It didn’t work.

After Monday’s boat work, we went out to see Fantastic Beasts, as we’d found a showing in English with Spanish subtitles. We also found a Mexican restaurant, so we prepped for the movie the authentic Gryffindor way, with tacos and cheladas. Even better, there was a massage station, and we came out of the theater and got the last chair massages of the night.

After Tuesday’s boat work, we took that offered reservation at Riesen. It turned out that their COVID policy was to seat only one table at a time, so we had the entire restaurant to ourselves for an over-four-hour tasting menu. Inspired food, so much so that even Jazz liked it, and well-chosen pairings. Local food, mostly from their garden, with some fermentation and molecular gastronomy touches to traditional wood-fire cooking on the patio outside. Also a cozy ambiance, beautiful silverware, and an esoteric mix of pop songs and exotic hip-hop. Definitely the best meal we’ve had since leaving the states, and probably the best duck breast Andrew has ever had. They even sent us home with a doggie-bag of purple-carrot cake, which provided two delicious breakfasts.

After that, we’d done everything we wanted to in Panama. Our engine was working, our boat was full… aside from our last batch of provisioning. The taxi driver who had taken us to the movie thater was from Colombia, and he told us where we could find Colombian imports in Panama City, including Aguila! The Panamanian lagers just don’t taste right with lime juice and salt. We hired him for the morning to take us around, and we bought some new produce, and more eggs, and of course some Aguila, because we realized that on the passage we could afford to give up a little sleeping space. Amazing how much you can fit onto a comparably little boat! (See us on the right of the mega-yacht?)

And then it was time to sail off and cross half the Pacific. Only 3875 miles, no sweat.