Back in Linton Bay, we packed away all our new purchases…

And settled into getting our engine put back together and ticking off all our “can of worms” projects: the ones that we thought were the greatest risk of exposing bigger problems and keeping us out of the Pacific. We’d bought some new o-rings for the heat exchanger, and given the state of the first one we took off, we figured we should probably change the other side first. Still, we vacillated: if it ain’t broke, don’t fix it? So we checked for leaks. Uh-oh; that’s not good.

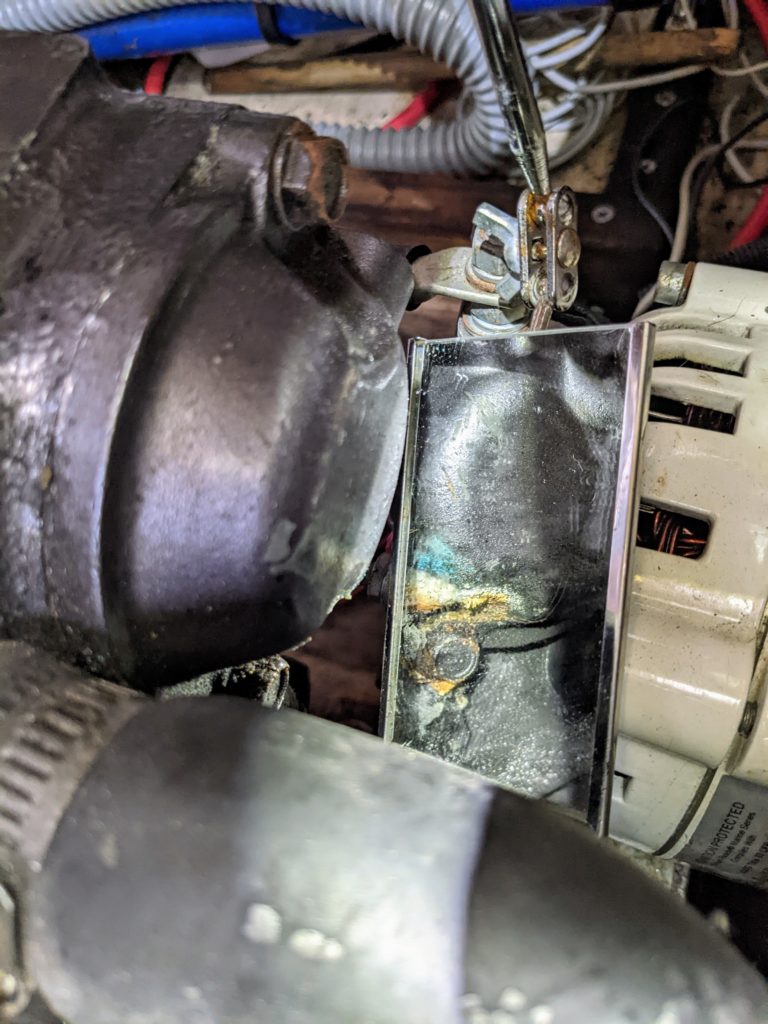

So we went to take the cover off the other side, and… well, the cover came off, but only part of one of the bolts came with it.

No problem; we’ve been down this road before; it’s just seized and we can get it out. Vice grips and WD-40 wouldn’t turn it, but there was enough space to try the impact driver, so we cut a slot into it. No dice. We went out and bought a set of easy-outs, and drilled a nice big hole in the center. When this didn’t produce motion, we called in a professional, who (encouragingly) did mostly the same thing, only with a bigger drill bit and easy-out, and a hole all the way through to get wd-40 to the other side. When this wouldn’t move the bolt either, he told us we’d have to take off the heat exchanger and bring it into the shop. So we did.

In the shop, with a vice and more power-tools, we were eventually able to drill out enough of the bit that there was a hole again. But the process destroyed most of the threads, so we would have to re-tap it for a larger bolt size.

By this point “we” (mostly “man monster” Andrew) had done enough damage to the tube stack that it needed to be welded back into smoothness. The heat exchanger block also needed a new surface, but that was because the corrosion had pitted the mating surface. So our welder fixed them both up. We got to a surface that was flat as far as we could tell, and hoped that some instant gasket would help plug any remaining gaps. (It seems to have worked.)

We figured that while we had it taken apart, we should take the opportunity to take care of any residual corrosion and fix up the paint. We didn’t get a perfect color match, but that’s fine; it’s just a living note to the next owner.

As we were putting the engine back together, fate decided to joke with us: the last bolt we put into the mixing elbow sheared off as we tightened it. Fortunately, we’d just coated it with TefGel, so getting it out was super easy. Unfortunately the only replacement on hand was a little too long; we would have to replace it when we could find a proper Yanmar bolt (which we ordered and then did).

Interspersed with this project, the next potential can of worms was our long-delayed check for “special water”. Several other Prout owners had mentioned drilling into the “sealed” spaces underneath the cockpit and salon and finding twenty or thirty gallons of water in each. So we bought some new hatch covers and the largest holesaw we’ve used yet, and drilled into the bottom of the cabinet below the captain’s chair. And we did find some special water, but it was closer to two gallons than to the twenty we were worried about, so we were reasonably happy.

More worrying, however, we noticed some cracks in the floor of the compartment, and started digging into them. And what we found was rather a lot of rotten wood. So we variously chipped and dremeled out the offending rot, and left it for a couple of days to dry, sometimes with a little bit of airflow assistance from a hair dryer.

When it had dried out, we started building it back up with epoxy and fiberglass. The new syringes came in handy for injecting epoxy between the remaining glass and wood, in case there was any separation that needed to re-attach. This was about when we realized that the new epoxy we’d bought was very much not slow-curing, and would have to be mixed in substantially smaller batches than the one that we water-cooled to keep it from catching fire. So that’s what we did, as we slowly added more layers of fiberglass.

We should mention that this new, fast-acting epoxy came from the Panamarina store, where the only information they could provide about it was the mixing ratio. On our way there, we saw our third monkey species, a howler just chilling in the trees, all black except for its giant tan testicles.

The check in the salon went much better: we drilled into the floor to find it full of bone-dry foam. So all we had to do was seal it back up again, filling in the gap with thickened epoxy and adding an extra layer of fiberglass over the top just for some extra structure. It would be a few more days before we got around to gluing the carpet back down.

The next can also proved manageable: one of the wooden support boards holding the watermaker in place had started to rot. We’d been unable to find a plug, so we had to turn off the fresh water while we worked, and that was the most annoying part of the project. Otherwise, the board came out with only a little bit of sawing. While we had it open, we figured we’d try to dry out and re-seal the passage where the coolant entered the refrigerator. Since the fridge was off, we had lots of spare power to help the drying along with a hair dryer, before sealing it back up with some extra insulation foam and putting the pump back in place with a new rot-resistant backing plate (actually a cutting board, after failing in 4 countries to find starboard).

The final can: why doesn’t our AIS seem to transmit any more? Andrew got on the phone to Garmin, and found out that there’s a debugging tool. Unfortunately we only had a one-foot mini-USB cable, so checking the error codes meant holding a laptop up in the closet. Once we could read the errors, we figured out that the unit’s GPS receiver had gone bad, and Garmin helpfully shipped us a replacement.

All this work went on in the back of the anchorage, with roll from one side and occasional wakes from these passing tourist boats. For a while there was also a loud clanging from the derelict boat next to us, but that stopped when its mast fell off.

A couple of other fun things. We caught Murphy, from Ddraig, starting to get bold and explore the ladder down from his treehouse.

Fortunately, this was in Ddraig’s last days on the hard; we got to have a last sundowner on shore together before they dropped back into the water.

So they got into the anchorage, but it was nearly time for us to leave it. Our shipment from MyUS came through, and we were pretty pissed to see how they packed it. MyUS is a consolidation company that receives your packages and forwards them to you anywhere, and that seems like a great idea except that everything about their execution is terrible. Here, they took a ten-pound laundry wringer and just plopped it on top of our new watermaker filters. A small child could have figured out that that was a bad idea, but MyUS doesn’t actually care whether your stuff breaks. We could go on for pages with concrete examples of why we hate them; avoid this company unless you have literally no alternative. You might not have one. (Hey entrepreneurs, want an easy way to make money from travelers? Start a clone company and make even a moderate effort not to be actively customer-hostile.)

In our final days in Linton, Jazz went to a store to provision, and confused the cashier by buying a whole box of butter instead of individual sticks or half-sticks. As we’re constantly figuring out how to do all our own work onboard, it’s nice to remember that, in the scheme of things, we’re still whole-box-of-butter-rich.

You are doing all the right things to minimize future problems and have a great skill set for solving what will come next. Proud of you both!