We sailed back to Christiansted from St Thomas in decent weather, but made bad time, and anchored in the dark next to the sunken sailboat that had been our neighbor on our last visit. Our pallet would be arriving soon, but hadn’t yet cleared customs, so we took a turn about Christiansted while we waited. A few highlights: the nicest park we passed seemed to be semi-permanently closed. A $32 steak, as served “for here” in styrofoam at a for-some-reason very highly rated barbecue restaurant. And finally, we saw this guy in a shop window.

I think we mentioned Andrew’s BCD breaking in St Vincent. Back in the sort-of-USA, we’d sent it for repairs. ScubaPro pronounced it dead, but offered a steep discount on a replacement, so we took them up on that. The new BCD arrived before the pallet, and when we went in to pick it up, we ended up walking out with new goggles for Jazz, which actually fit her. The story of St Croix would end up including a lot of upgrades to make our dive kits more comfortable.

And then, late in the afternoon, we got word that the pallet was in and would be available the next morning! So we rented ourselves a mini-van. (After spending a week arguing about who’s going to change the diaper on a leaky pump, we were extra amused to find ourselves driving a mini-van, the stereotypical parent-mobile.) It was Cinco de Mayo, and took the opportunity to go visit a friend. We’d met Tom in Luperon, and he happened to be staying in a marina a few miles down the road. So we swung by, picked him up, and went out for tacos and drinks. We had a great time catching up – it’s funny what a small world the sailing community is.

Picking up the pallet went smoothly, until we checked against our list of tracking numbers and found one package was missing. The warehouse told us that that was everything, and it must be on the next boat. (Damn! Another week, another car rental….) But when we called Miami, they told us the missing package had already been sent. With a little digging, we were able to get the warehouse guys a description of the big long box of fabric, and they found it tucked away on a different shelf.

Mystery solved, all packages accounted for, we “celebrated” with a stop at the local barbecue chicken “shack”.

We got the car unloaded, over several dinghy rides, took a brief tour of the north side of the island, and got the rental car back right on time.

This is when, by accident, we discovered that the kombucha shop we’d walked by several times actually had daily yoga classes at their upstairs studio. So, for the last few days in Christiansted while we sorted boxes and picked up extra parts at the local chandlery, this would become part of our routine.

At the same place, we met someone working tech for the local community theater, and she told us that they had a show that was just opening. So we got to see actual, live theater, in person, for the first time since the pandemic!

OK, we know what you’re thinking. “Enough about the good times. You promised me potties!” Well, here we go. I think we’ve mentioned that Jazz hated our old toilet, once in a while, but it’s not something we like to spend lots of time dwelling on. But, to really grasp the importance of the next part, you have to imagine her telling Andrew about once a week, for two years, that she would rather use a bucket. The vacuum action, part of what made it “super reliable”, meant that the seat was nearly always ringed with salt water, and the old, stained and cracked seat and lid had proved prohibitively difficult to replace. It had started to fail on us, and we’d ordered a replacement in the pallet, but of course it decided to give up the ghost right before our friends visited us in St John. Super embarrassing. Our creative re-rig also left us with a hole in the wall.

All of that to say, Jazz was super excited when it was time to install the new one.

Having picked up all the extra parts we needed in Christiansted, we decided to do the install in Frederiksted. That way we’d have flatter water, and better access to on-shore facilities while ours were out of commission. The first step: clear all the other stuff out of the bathroom, which meant Captain’s litter box would live in the cockpit for a while. We’re lucky: as much as he can be a pill about some things, Captain really does not care where his box is, so long as he can get to it. He is not at all embarrassed about this photo.

A new electric head means new wiring, and since that part went smoothly, we’ll start there. We decided to run power from a set of power posts in the salon, but those had grown too many legs and needed to become bus bars. With that done, we ran new wires under the couch, behind the bathroom sink, under where the toilet would eventually go, and up to the site of the new control cable. Simple and straightforward, and we’d even bought the right amount of wire!

The rest of the installation went less smoothly. We hadn’t expected the old bolt holes to match the new toilet, so we were not disappointed when we couldn’t re-use any of them. But what took us by surprise was that all the old holes had been drilled and… that’s it, just drilled and nothing else. Why is that a nasty surprise? Well, the base of the toilet is cored fiberglass, meaning that there’s fiberglass on the top and bottom and something else in the middle. That something else is usually wood. Fiberglass takes water like a champ, but when wood gets and stays wet, it can rot. It also turns out that showers are often wet, and since the toilet is right next to the shower, there’s going to be some leakage through the holes. To keep the water out of the wood when you drill through core, standard practice is to seal the edges. Whoever installed the old toilet hadn’t done this. So we found that instead of a straightforward patch, we would have to remove a bunch of rotten wood, and fill the space with a thickened epoxy. (If it had been much worse, this might not have been enough, and we might have needed to cut the whole panel open and replace the core. Fortunately, the rot didn’t seem to extend very far.)

You might notice that the hole in the last picture doesn’t look very full, and Andrew isn’t wearing much clothing. That’s because this is the tropics and it’s hot. The hotter epoxy gets, the faster it cures, and since curing releases yet more heat, too much epoxy curing all in one place can make problems. So even using a slow hardener, we had to pour the larger holes in a couple of layers, pausing in between. Eventually we realized that we could get around this to some extent for the holes we were just trying to seal, by fitting in a mold and leaving the center empty. (Thank you, probiotic gummy jar and coke bottles.) This came in handy when we realized we hadn’t quite made the new exhaust hole big enough. And then again the next day, when we realized we would have to repeat this whole process for the holes inside the closet, which had also not been sealed properly. Facepalm. The epoxy takes a few hours to cure before it can be worked, drilled, or gel-coated over, which meant that each of these discoveries cost us another extra toilet-less day. Jazz got her wish to use the bucket, and still believes it is better than the old toilet.

On the bright side, the delays did give us an excuse to eat more breakfasts on shore. Polly’s on the Pier!

We also took the opportunity, with everything out of the closet, to make some changes and repairs to the headliner. We’d have taken it out entirely, but Villa can be a little loud going into the waves, and the new intake pump was going to be right under Captain’s litter box, so we figured we could use all the noise reduction we can get. Wouldn’t want to literally scare the shit out of the cat. At the same time, having foam headliner go all the way to the floor in a potentially wet room was a bad idea with predictable consequences. After the leaky pump incident, all the black-water contaminated foam had to go.

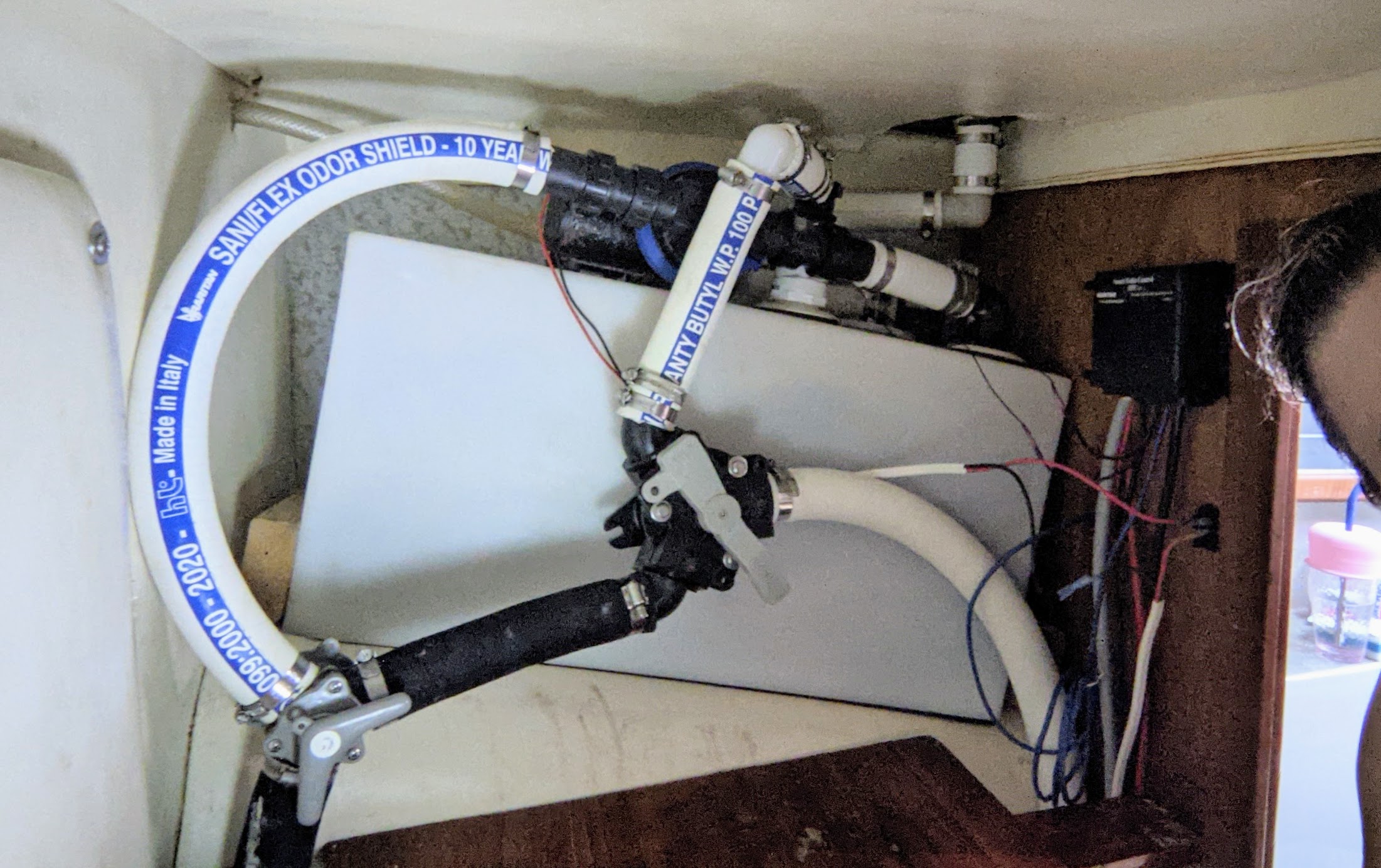

Eventually, all the epoxy and headliner adhesive dried, and we were able to do the final install. One of the perks: getting rid of the tangle of ugly homemade adapters we’d had to use with the old macerating discharge pump.

The final trim actually ended up being almost as much work as the plumbing. Once we’d started on the headliner, we couldn’t leave the trim hanging off in the rest of the bathroom, so it was GooGone and Gorilla contact adhesive all around the top edge of the room. We also had to patch the hole in the wall, fortunately only partially as it would become the site of the new control panel. We cut a spare piece of very hard wood close to size, and then Jazz sanded it down on the back deck with the coarsest paper we had on hand, 120 grit. (If you’re not familiar with sandpaper, this is too fine to remove a lot of material fast, so she was out there for a long time.) Then steady-handed Jazz had to cut new tiles to cover the rest of the wall. End result? A working toilet and a much cleaner-looking bathroom.

With the room put back together, Captain made sure we knew where to put his litter box away. Final story: we had a minor issue when we first took it offshore to pump out, and Andrew ended up doing a bunch of useless fiddling before figuring out how to get the discharge pump primed. He hopes never to have to put his face up in that cabinet again.

Lots of work, but the end result looks great!